Latest News

Photo of the week (17/07/2022)

Seen here is our newest van, a Chrysler Pacifica. Its all wheel drive, gets good gas mileage, has tons of storage, and is comfortable to drive!

PHOTO OF THE WEEK (29/06/22):

Introduction to PACS and SACS Establishment

Geopro regularly establishes permanent airport geodetic control (Primary and Secondary Airport Control Stations). This type of work is both very specialized and physically demanding! A typical project takes about six months to complete and requires coordination with the Airport, Consulting Engineers, the NGS, and the FAA.

After the monuments have been set and surveyed, there is an extensive reporting and data processing workflow that is commonly called “BlueBooking.” The specialized software that is required to complete this process is still DOS based and requires many years of training to do correctly. Geopro’s staff have been performing PACS/SACS establishment for over 20 years and still find these projects to be some of the most challenging to complete!

Photo of the week (24/06/22):

A late night geodetic observation for a PACS and SACS project turned foggy, resulting in this spooky airport beacon.

A tiny, volcanic island in eastern Indonesia.

Geopro spent last week at zero degrees latitude on the opposite side of the planet! Another successful project in Asia, and our third in Indonesia. The project was performed to document the existing runway and obstacle conditions to support procedure development and improve safety. Geopro led a team of Indonesian experts to survey more than 100 features within 5km of the airfield.

Surveying Two Airports in Guatemala

Geopro spent a fantastic week surveying airports in Guatemala and enjoying the local sites and cuisine. Our airport surveying team has now visited 20 countries around the world! While in Guatemala our Team also visited the Tikal Mayan Temples and hiked a volcano!

An evaluation of drone accuracy for obstruction mapping

This weekend we performed a quantitative analysis to evaluate the accuracy of drone based photogrammetry results. For some time I’ve been very interested to see how well a photogrammetrically derived point cloud would identify the tops of trees or man-made objects, to see how useful this technology may actually be in the performance of obstruction surveys. I want to strongly emphasize this research project was not completed near an airport. Flying a UAV near an airfield is extremely dangerous. Our test site was carefully selected at a secluded location, miles from the nearest airfield.

We utilized a Geopro customized multi-rotor carrying a 12.4mp camera with 20mm focal length flying at an AGL of 100 meters. The 4000×3000 resolution photos resulted in a ground sample distance (GSD) of 4.3 cm (0.14 feet) per pixel. This height was selected due primarily to my comfort level; I wanted to stay below 400 feet and a GSD under 5cm seemed like a good idea.

We began by setting photogrammetric ground control around the site, consisting of eight points around the perimeter and center of the project. We collected the points using a Trimble R8 Model 3, receiving corrections from the Ohio VRS network. I assume the final positions are accurate within 2cm both horizontally and vertically, though we have not rigorously verified the positions. Work was completed in Ohio State Plane South using metric units of measurements. Geoid 12B was utilized to compute orthometric heights.

Next we established temporary survey points and utilized a recently calibrated 1” Trimble total station (5601) to measure the top of objects using Direct-Reflect technology. In all we shot the top of 36 trees, 6 posts, and two light poles. Some of the trees were in full leaf-on condition, others were dead or unifoliated.

After setting the points we launched our drone, the camera setting were manually applied:

- ISO 100 to get clean photos with minimal noise

- Aperture limit of f/2.8

- Shutter speed limit of 1/400 second

In total we collected 127 photos across the project area, flying two missions at 90 degrees to each other. The images are generally sharp with minimal motion blur.

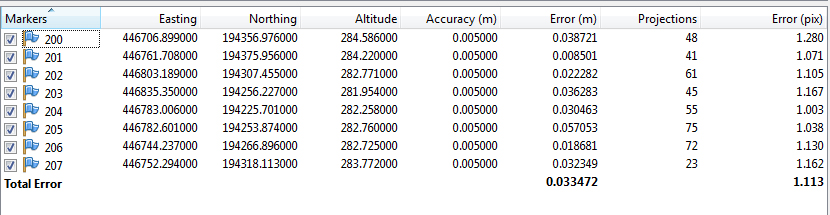

The photos were then loaded into Agisoft Photoscan and processed on ultra-high settings to avoid any image quality reduction. The GCPs and photo alignment results in an average reference point error of just over 3cm.

The final point cloud had just under 79 million points. These points were exported as a .LAS for analysis. A height-field model was then produced for visual inspection:

The resulting model looked impressive.

The resulting model looked impressive.

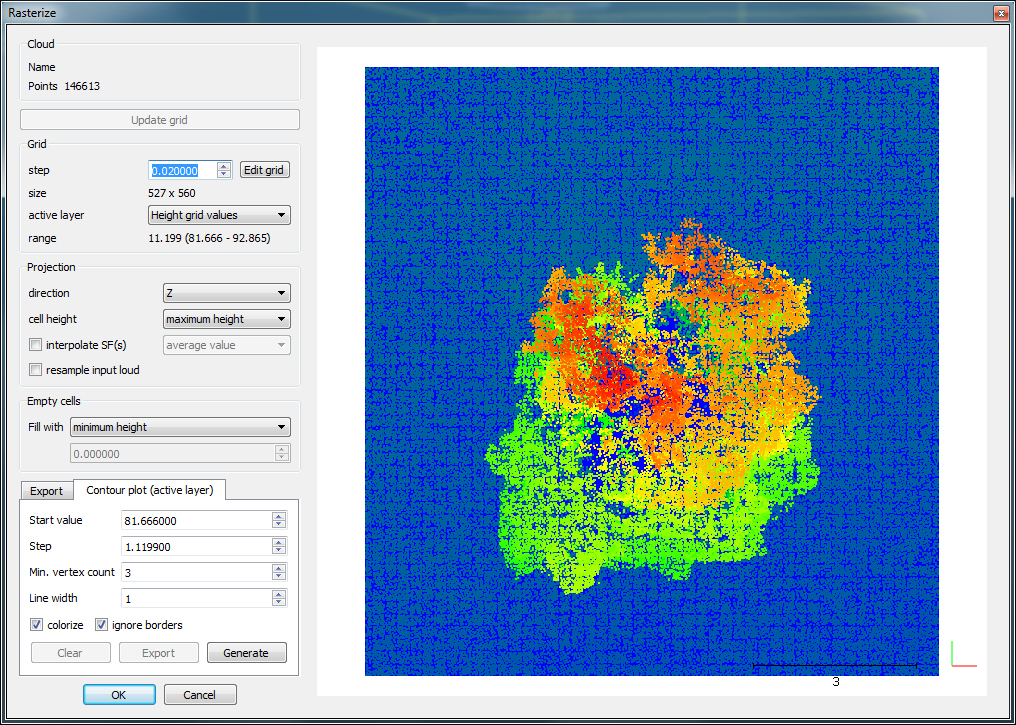

The exported .LAS file and terrestrially measured points were then loaded into Cloud Compare. The area around each point was segmented into its own cloud for analysis using the height-field rasterization tool using a 2cm grid and projecting the maximum height.

Cloud Compare’s Height Field Tool

Cloud Compare’s Height Field Tool

Note, Cloud Compare required a coordinate shift during import in order to maintain precisions. A -200m offset was applied as a simple shift, 292.865 becomes 92.865.

The results of the comparisons can be categorized by object type:

Man-made objects typically were not accurate unless they have a cross sectional area substantially larger than the GSD. Not a single post (10cm diameter) was identified by the photogrammetric software, on average missing by 2.21 meters (7.25 feet), the height of the post. Street lights with their large (60cm) top housing were accurately measured within 0.25 meters (0.82 feet). It is clear that for an object to be accurately measured, it must have a cross-sectional diameter greater than 2 times the GSD. In this case the GSD was 4.27cm and a 10cm post was not detected. I may do more testing to try to confirm or better approximate this requirement but is seems the sampling theorem may generally still be true here.

Trees with substantial and healthy canopy were measured reliably, on average within 0.45 meters (1.48 feet):

Trees with dead or no leaves were not accurate, on average missing by 2.72 meters (8.9 feet): The above tree may look accurate, but Agisoft missed the top of tree by 2.51m (8.2ft).

The above tree may look accurate, but Agisoft missed the top of tree by 2.51m (8.2ft).

The following table compiles the results:

| Description | Count | Average | Best | Worst |

| Trees (healthy) | 30 | 0.43 m | 0.03 m | 1.56 m |

| Trees (no leaves) | 6 | 2.72 m | 2.30 m | 3.50 m |

| Posts | 6 | 2.21 m | 2.11 m | 2.31 m |

| Street Light | 2 | 0.27 m | 0.28 m | 0.26 m |

Looking at the results in their entirety, without differentiation between object types, it is worth noting the average vertical error was 1.08 meters (3.36 ft), just slightly more than the FAA 1A accuracy code.

Note: No evergreen trees were mapped as part of this effort, but based on their geometry, I would guess they tend to be similar to unfoliated tree results and would also be unsuitable for this approach.

My conclusion is that while drone technology offers a lot of promise, it cannot be exclusively relied upon, especially when man-made objects or slender natural features exist. A power pole without lighting or an aerial wire, for example, would go completely undetected using his drone technique. Those very dangerous objects are critical and must be accurately located during an obstruction survey, but a drone only approach would likely miss them completely.

It is important that the drone imagery be further analyzed by trained photogrammetrists to identify and measure missing obstacles. Also critical is the quality control measures performed by ground-surveyors, to measure obstacles using terrestrial techniques and ensure that no errors occurred during the automated processing of drone images. Relying on the software alone to compute obstructions could be a potentially disastrous risk, based on what we’ve seen here. With lives on the line it is essential that specially trained and skilled professionals are performing the analysis and understand the limitations of the technology.

The reality of PhoDAR

I’ve been hearing the term PhoDAR (photogrammetric detection and ranging) a lot lately. There are numerous automated “photogrammetry” software packages being offered today that create point clouds from photos. The software looks phenomenal and many boast of incredible accuracy. Wikipedia currently lists more than 60 such solutions, with big name vendors such as AutoDesk, Bentley, Microsoft, and Trimble on the list.

These software solutions utilize camera based techniques that rely strongly on a workflow called Structure from Motion (SfM). During the SfM process, 2-Dimensional photographs of a scene are obtained from many different perspectives, the software then analyze the photos looking for similar features and patterns. Using this redundancy the software estimates a camera calibration as well as transformations between the different camera views. Typically this is done in multiple steps with an initial “sparse processing” to determine camera and view parameters, and then a “dense reconstruction” is performed that processes the images in overlapping chunks. This technique is computationally intense, but uses statistics to estimate reality and come up with a point cloud. If the same pattern matches in multiple photos a level of confidence can be estimated that point actually exists… even if it doesn’t.

I’ve been exploring this technology for nearly a decade and it has been interesting to see the market develop. In one recent Whitepaper eBee (using Pix4D I’m guessing) claims they can achieve an accuracy of 3 cm (Horizontally) to 5cm (Vertically). My guess is the key word there is “can.” Just because it can be done, doesn’t mean it is done. (How’s that for a sentence?)

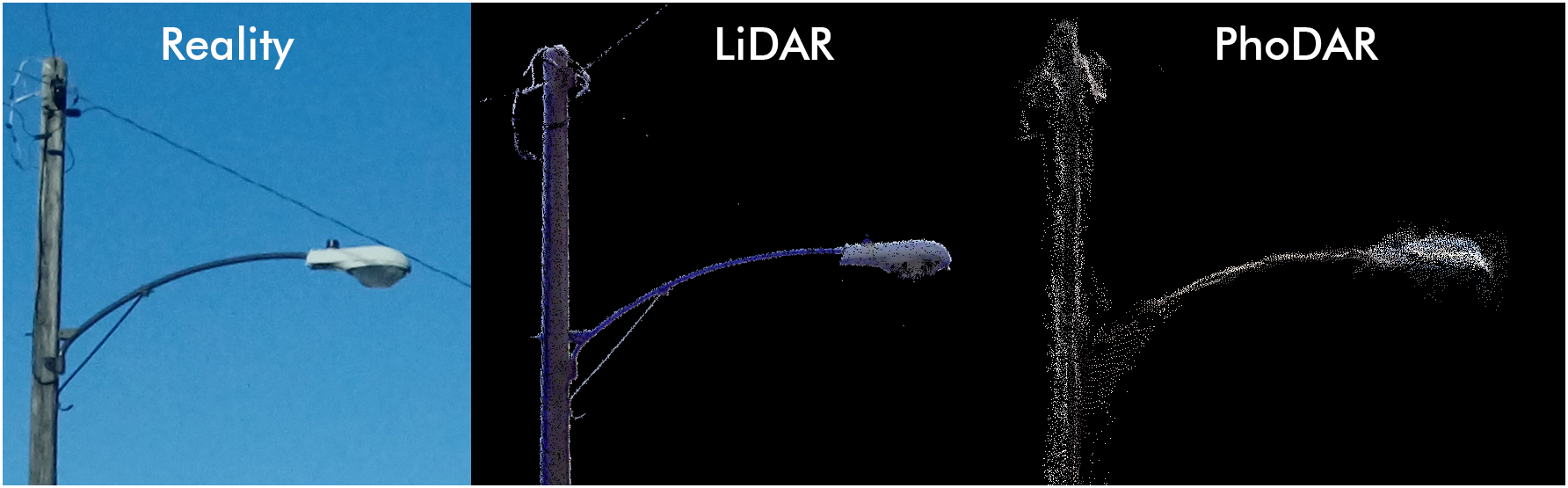

If you’ve ever tried out this type of software you’ll notice glaring issues if you look at the data closely. An example of this is provided below. The far left is a photograph of the actual pole, the middle data was collected with our Faro terrestrial scanner, and the far right was computed using a very popular (and expensive) software SfM/PhoDAR/Photogrammetry package. Reality and LiDAR are very clearly in agreement, but the limitations of structure-from-motion based solutions are apparent. This point cloud was computed using 30+ images at an altitude of 150 feet (more to come on this example later).

One of these is not like the others.

It is interesting technology and those high-altitude demo videos I keep seeing are impressive, but I don’t think it’s quite a substitute for professional grade mapping. As this software becomes more accessible, there’s a potential danger to the public when used by drone owners who may not know the limitations. Be careful out there and stay informed, check back here often for more on this topic as we continue to explore new geospatial technologies.

PhoDAR Light Pole Sample

by geopro

on Sketchfab

LIDAR-TENTH

by geopro

on Sketchfab

Please comment below and share your opinion on PhoDAR and other automated photogrammetry solutions. Does automated photogrammetry pose a risk to the public?

Aviation Training and Certification

Over our last decade of providing aeronautical surveying services, we have often been asked to provide training to government agencies and airport authority personnel on how to properly conduct and aeronautical survey. In response to this common request, Geopro has developed a training program available to airport authorities who wish to better understand the concepts and correct approach to conducting an AGIS-style survey.

Our survey training program focuses on the five major areas of an aeronautical survey: geodetic control, runway surveying, navigational-aid surveying, obstacles, and data reductions and reporting for ICAO specifications. The training provides real-world experience and is performed at the airfield of the client’s choosing. It also includes numerous hours of office training, where trainees are first introduced to the proper procedure for all phases of the survey process, from determining the correct runway end locations to identifying survey points for common navigational aids.

Though some training programs exist for surveying, ours is the only program that focuses on all parts of the aeronautical survey process. Another unique benefit of our program is the combined classroom and field survey training with certification exam. We offer two levels of training and certification: 40 and 80 hour programs that will take a novice airport surveyor to the certified and efficient status within two weeks.

An application process is required to be admitted to the training and not all candidates will qualify. Basic knowledge of survey instrument operation, GPS, and data processing software is required. Students who successfully complete the program will be awarded a certificate of completion for the course.

Procedure Design

Geopro Consultants has established a worldwide network of procedure designers skilled in all aspects of airspace analysis and procedure development, including RNP Procedures to improve access and safety into often remote, but highly desirable airfields. Our teams routinely deploy to sites across the globe to perform high-accuracy data surveys to support procedure development. Your airport’s location has value; make the most of it by improving your approach procedures and maximizing your current investment.

Geopro Consultants has established a worldwide network of procedure designers skilled in all aspects of airspace analysis and procedure development, including RNP Procedures to improve access and safety into often remote, but highly desirable airfields. Our teams routinely deploy to sites across the globe to perform high-accuracy data surveys to support procedure development. Your airport’s location has value; make the most of it by improving your approach procedures and maximizing your current investment.

Our team has also worked with airports within the United States to optimize existing procedures in conjunction with the FAA. Many of our procedure designing partners are ex-FAA officials with an intimate understanding of the FAA process and can spend the time necessary to understand the issues impacting your airport. A better understanding of the facts previously considered by the FAA combined with knowing what changes could improve procedures often leads to more efficient usage of available tree clearing funds.

If your airport desires updated, improved procedures and reduced minimums, please contact us today to learn how our services may help your airport grow.